Lead wire of Electrical Device

Lead wire of Generator and Motor, Wiring of Ignition, Wiring of moving, Wiring of Power Plant

Wiring of Halogen Free application

|

1) Conductor : Tin Coated Copper / Nickel Plated Copper

2) Insulation : Silicone Rubber

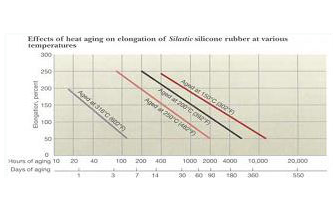

1) Good Heat Resistance, Cold Resistance (-60 ∼180℃)

2) Easy wiring with high flexible

3) High tearing Resistance and good sheath strength

4) Suitable for impact resistance and high tension application

| Item | Properties | Test Condition | ||

|---|---|---|---|---|

| Appearance | Shall not have pollution, scratch, bubble on the surface and other harmful defects. | * Naked Eye | ||

| Dielectric Strength | Shall withstand without breakdown 1 Min. in below table 5 | * In the water | ||

| Insulation Resistance/td> | Shall be satisfied value in below table 5 | * 20±2℃ in the water | ||

| Physical Properties of Insulation | Tensile Strength | Not Less than 0.40㎏f/㎟ | * In the air | |

| Elongation | Not less than 150% | |||

| Aged | Tensile Strength | (1) Not less than 70% of original result (2) Not less than 0.352㎏f/㎟ |

* Aging Condition 220±3℃/96hrs | |

| Elongation | (1) Not less than 65% of original result (2) Not less than 100% | |||

| Heat Shock Test | Specimen shall not show evidence of cracking | * 220± 5℃ × 24hrs | ||

| Cold Bend Test | Specimen shall not show evidence of cracking | * -10± 2℃ × 4hrs | ||

1) 600V Grade

| Conductor | Insulation Thickness (㎜) | Braiding Thickness (㎜) |

Avg. Overall Diameter (㎜∮) | Max. Overall Diameter (㎜∮) |

Dielectric Strength (v) | |

|---|---|---|---|---|---|---|

| Cross-sectional Area SQ (㎟) | Composition(cores/㎜Ø) | |||||

| 0.75 | 30 / 0.18 | 1.10 | 3.35 | 3.90 | 2,000 | 200 |

| 1.25 | 50 / 0.18 | 1.10 | 3.67 | 4.30 | 2,000 | 150 |

| 2.00 | 37 / 0.26 | 1.10 | 4.03 | 4.60 | 2,000 | 150 |

| 3.50 | 44 / 0.32 | 1.10 | 4.91 | 5.30 | 2,000 | 100 |

| 5.50 | 35 / 0.45 | 1.10 | 5.30 | 5.90 | 2,000 | 80 |

| 68 / 0.32 | 1.10 | 5.58 | 5.90 | |||

| 8.00 | 50 / 0.45 | 1.10 | 5.90 | 6.50 | 2,000 | 70 |

| 99 / 0.32 | 1.10 | 6.35 | 6.50 | |||

| 10.00 | 7 / 27 / 0.26 | 1.10 | 6.88 | 7.30 | 2,000 | 70 |

| 14.00 | 88 / 0.45 | 1.10 | 7.07 | 8.30 | 2,000 | 70 |

| 22.00 | 7 / 20 / 0.45 | 1.40 | 9.89 | 10.40 | 2,000 | 60 |

| 30.00 | 7 / 27 / 0.45 | 1.80 | 10.90 | 11.60 | 2,500 | 60 |

| 38.00 | 7 / 34 / 0.45 | 1.40 | 12.05 | 12.60 | 2,500 | 50 |

| 50.00 | 19 / 16 / 0.45 | 1.80 | 14.00 | 14.80 | 2,500 | 50 |

| 60.00 | 19 / 20 / 0.45 | 1.80 | 15.30 | 16.20 | 2,500 | 40 |

| 80.00 | 19 / 27 / 0.45 | 2.30 | 17.10 | 17.90 | 3,000 | 40 |

| 100.00 | 19 / 34 / 0.45 | 2.30 | 19.74 | 20.70 | 3,000 | 40 |

| 125.00 | 19 / 42 / 0.45 | 2.30 | 21.43 | 22.30 | 3,000 | 40 |

| 151.00 | 27 / 34 / 0.46 | 2.30 | 22.77 | 24.30 | 3,000 | 40 |

| 200.00 | 37 / 34 / 0.46 | 2.90 | 27.07 | 28.10 | 3,000 | 40 |

| 250.00 | 37 / 42 / 0.46 | 2.90 | 29.46 | 30.50 | 3,000 | 40 |

| 325.00 | 37 / 55 / 0.45 | 2.90 | 32.83 | 34.83 | 3,000 | 40 |

2) 1,500V Grade

| Conductor | Insulation Thickness (㎜) | Braiding Thickness (㎜) |

Avg. Overall Diameter (㎜∮) | Max. Overall Diameter (㎜∮) |

Dielectric Strength (v) | |

|---|---|---|---|---|---|---|

| Cross-sectional Area SQ (㎟) | Composition(cores/㎜Ø) | |||||

| 1.25 | 50 / 0.18 | 2.00 | 5.47 | 5.67 | 5,000 | 200 |

| 2.00 | 37 / 0.26 | 2.00 | 5.83 | 6.30 | 5,000 | 200 |

| 3.50 | 44 / 0.32 | 2.00 | 6.71 | 7.10 | 5,000 | 150 |

| 66 / 0.26 | 2.33 | 7.50 | 7.70 | |||

| 5.50 | 68 / 0.32 | 2.00 | 7.38 | 7.70 | 5,000 | 150 |

| 8.00 | 99 / 0.32 | 2.00 | 8.15 | 8.30 | 5,000 | 100 |

| 10.00 | 7 / 27 / 0326 | 2.50 | 9.68 | 8.98 | 5,000 | 100 |

| 14.00 | 88 / 0.45 | 2.50 | 9.87 | 10.60 | 5,000 | 100 |

| 22.00 | 7 / 20 / 0.45 | 2.50 | 12.09 | 12.70 | 5,000 | 90 |

| 30.00 | 7 / 27 / 0.45 | 2.50 | 13.10 | 13.90 | 5,000 | 80 |

| 38.00 | 7 / 34 / 0.45 | 2.50 | 14.25 | 14.90 | 5,000 | 70 |

| 50.00 | 19 / 16 / 0.45 | 2.50 | 15.40 | 16.10 | 5,000 | 60 |

| 60.00 | 19 / 20 / 0.45 | 2.50 | 16.68 | 17.40 | 5,000 | 60 |

| 80.00 | 19 / 27 / 0.45 | 2.50 | 18.50 | 19.30 | 5,000 | 50 |

| 100.00 | 19 / 34 / 0.45 | 3.00 | 21.14 | 22.10 | 5,000 | 50 |

| 125.00 | 19 / 42 / 0.45 | 3.00 | 22.83 | 24.00 | 5,000 | 50 |

| 151.00 | 27 / 34 / 0.46 | 3.00 | 24.17 | 25.80 | 5,000 | 40 |

| 200.00 | 37 / 34 / 0.46 | 3.00 | 27.27 | 28.40 | 5,000 | 40 |

| 250.00 | 37 / 42 / 0.46 | 3.50 | 30.66 | 31.90 | 5,000 | 40 |

2) 3,300V Grade

| Conductor | Insulation Thickness (㎜) | Braiding Thickness (㎜) |

Avg. Overall Diameter (㎜∮) | Max. Overall Diameter (㎜∮) |

Dielectric Strength (v) | |

|---|---|---|---|---|---|---|

| Cross-sectional Area SQ (㎟) | Composition(cores/㎜Ø) | |||||

| 2.00 | 37 / 0.26 | 3.00 | 7.83 | 8.40 | 8,000 | 200 |

| 3.50 | 44 / 0.32 | 3.00 | 8.71 | 9.10 | 8,000 | 200 |

| 5.50 | 68 / 0.32 | 3.00 | 9.38 | 9.70 | 8,000 | 200 |

| 8.00 | 99 / 0.26 | 3.00 | 10.15 | 10.40 | 8,000 | 150 |

| 10.00 | 7 / 57 / 0.45 | 3.00 | 10.68 | 11.00 | 8,000 | 150 |

| 14.00 | 88 / 0.45 | 3.00 | 10.87 | 11.60 | 8,000 | 150 |

| 22.00 | 7 / 20 / 0.45 | 3.00 | 13.09 | 13.80 | 8,000 | 100 |

| 30.00 | 7 / 27 / 0.45 | 3.00 | 14.10 | 14.90 | 8,000 | 90 |

| 38.00 | 7 / 34 / 0.45 | 3.00 | 15.25 | 15.90 | 8,000 | 80 |

| 50.00 | 19 / 16 / 0.45 | 3.50 | 17.40 | 17.70 | 8,000 | 80 |

| 60.00 | 19 / 20 / 0.45 | 3.50 | 18.70 | 19.701 | 8,000 | 70 |

| 80.00 | 19 / 27 / 0.45 | 3.50 | 20.50 | 21.50 | 8,000 | 70 |

| 100.00 | 19 / 34 / 0.45 | 3.50 | 22.14 | 23.30 | 8,000 | 60 |

| 125.00 | 19 / 42 / 0.45 | 3.50 | 23.83 | 24.90 | 8,000 | 50 |

| 150.00 | 27 / 34 / 0.46 | 3.40 | 25.17 | 26.80 | 8,000 | 50 |

| 200.00 | 37 / 34 / 0.46 | 4.00 | 29.27 | 30.40 | 8,000 | 40 |

| 250.00 | 27 / 42 / 0.46 | 4.00 | 31.66 | 35.90 | 8,000 | 40 |

2) 6,600V Grade

| Conductor | Insulation Thickness (㎜) | Braiding Thickness (㎜) |

Avg. Overall Diameter (㎜∮) | Max. Overall Diameter (㎜∮) |

Dielectric Strength (v) | |

|---|---|---|---|---|---|---|

| Cross-sectional Area SQ (㎟) | Composition(cores/㎜Ø) | |||||

| 2.00 | 37 / 0.26 | 3.33 | 8.50 | 9.00 | 15,000 | 200 |

| 8.00 | 99 / 0.32 | 5.00 | 14.15 | 14.50 | 15,000 | 200 |

| 10.00 | 7 / 27 / 0.45 | 5.00 | 14.68 | 14.70 | 15,000 | 200 |

| 14.00 | 88 / 0.45 | 5.00 | 14.84 | 15.50 | 15,000 | 200 |

| 22.00 | 7 / 20 / 0.45 | 5.00 | 17.09 | 17.90 | 15,000 | 150 |

| 30.00 | 7 / 27 / 0.45 | 5.00 | 18.10 | 19.10 | 15,000 | 150 |

| 38.00 | 7 / 34 / 0.45 | 5.00 | 19.25 | 20.10 | 15,000 | 100 |

| 50.00 | 19 / 16 / 0.45 | 5.00 | 20.40 | 21.40 | 15,000 | 100 |

| 60.00 | 19 / 20 / 0.45 | 5.00 | 21.68 | 22.80 | 15,000 | 100 |

| 80.00 | 19 / 27 / 0.45 | 5.00 | 23.50 | 24.60 | 15,000 | 90 |

| 100.00 | 19 / 34 / 0.45 | 5.00 | 25.14 |

26.30 | 15,000 | 80 |

| 125.00 | 19 / 42 / 0.45 | 5.00 | 26.83 | 28.00 | 15,000 | 70 |

| 150.00 | 27 / 34 / 0.46 | 5.00 | 28.17 | 29.90 | 15,000 | 70 |

We certify that there is not contained Hazardous substances in this product such as Lead(Pb), Mecury (Hg), Cadmum (Cd), Hexavalent Chromium(Cr+6), PPB, PBDE.