1) With insulated on a pair of conductors almost same EMF with thermocouple from low temperature to high temperature,

Connect between the terminal of thermocouple and measuring point with wire.

To compensate error of temperature change on terminal of thermocouple is Compensating Wire.

2) The wire made by same material of thermocouple is called Extension Wire.

| Thermocouple Type and Material KS C 1602 | Thermocouple Wire Type and Material ( KS C 1609 ) | Symbol | ISA-MC 96.1-1982 (ANSI MC 96.1) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Material of Pole | Segmentation | Temp. Range(℃) | Tolerance | Temp. Range(℃) | Tolerance | |||||||

| Type | Ex. Symbol | Material | Positive(+) | Negative(-) | Normal | Precise | Normal | Precise | ||||

| B | - | Platinum Rhodium 30% Platinum Rhodium 6% | SCR COPPER | SCR COPPER | G | 0~100 | - | - | BC | 0~100 | +0.000㎷ -0.033㎷ |

- |

| R | - | Platinum Rhodium 13% Platinum | SCR COPPER | COPPER NICKEL ALLOY | G | 0~150 | +3 -7 |

- | RX SX | 0~200 | ±0.057 ㎷(±5) |

- |

| S | - | Platinum Rhodium 10% Platinum | H | |||||||||

| K | CA | CHROMEL ALUMEL | CHROMEL | ALUMEL | G | -20~150 | ± 2.5 | ± 1.5 | KX | 0~200 | ± 2.2 | - |

| H | ||||||||||||

| W | IRON W-CONSTANTAN | IRON | W-CONSTANTAN | G | -20~150 | ± 3 | - | WX | - | - | - | |

| H | ||||||||||||

| V | COPPER V-CONSTANTAN | SCR COPPER | V-CONSTANTAN | G | -20~100 | ± 2.5 | - | VX | - | - | - | |

| E | CRC | CHROMEL E-CONSTANTAN | CHROMEL | E-CONSTANTAN | G | -20~150 | ± 2.5 | - | EX | 0~200 | ± 1.7 | - |

| H | ||||||||||||

| J | IC | IRON J-CONSTANTAN | IRON | J-CONSTANTAN | G | -20~150 | ± 2.5 | - | JX | 0~200 | ± 2.2 | ± 1.1 |

| H | ||||||||||||

| T | CC | COPPER T-CONSTANTAN | COPPER | T-CONSTANTAN | G | -20~150 | ± 2.0 | ± 1.0 | TX | -60~100 | ± 1.0 | ± 0.5 |

| Insulation Material | Symbol | Temp. Range(℃) | Water Resistance | Oil Resistance | Solvent Resistance | Insulation Resistance(MΩ/Km) |

|---|---|---|---|---|---|---|

| PVC | V | -20~60 | ○ | △ | △ | 60 |

| Heat Resistant PVC | HV | -20~105 | ○ | △ | △ | 60 |

| PE | E | -60~60 | ○ | △ | X | 2,500 |

| XLPE | C | -60~125 | ○ | △ | X | 2,500 |

| PET | P | 60~150 | ◎ | ◎ | ◎ | 1,500 |

| EP | EP | -40~80 | △ | X | △ | 80 |

| Nylon | N | -40~120 | ◎ | ◎ | ◎ | 1,500 |

| Polyimide | PI | -250~300 | ◎ | ◎ | ◎ | 1,500 |

| Teflon | F | -100~250 | ◎ | ◎ | ◎ | 1,500 |

| Silicone Rubber | K | -60~200 | ○ | X | ○ | 80 |

| E-Glass | G | -73~480 | X | △ | ○ | 0.1 |

| S-Glass | S | -73~705 | X | △ | ○ | 0.1 |

| Ceramic Fiber | - | -18~1205 | X | △ | ○ | 0.1 |

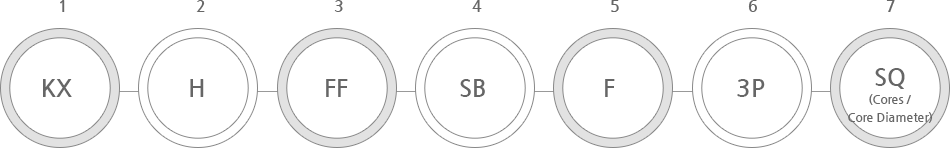

| 1) Type | 2) Segmentation | 3) Material of Insulation and Sheath | 4) Shield Type | 5) Shape | 6) Cores Coposition | 7) Conductor size and Composition |

|---|---|---|---|---|---|---|

| KX, JX, EX, TX, NX, SX |

G : General Normal H : Heat Resistant Normal GS : General Precise HS : Heat Resistant Precise |

V : Vinyl HV : Heat resistant Vinyl F : Teflon ( FEP ) G : Glass Fiber |

SB : Tin Coated Copper Braiding AL : Aluminum Mylar Tape CU : Copper Tape |

F : Flat Type R : Round Type |

3P : 3 Pair |